PP Melt Blown Filter Cartridges, PP Melt Blown Filter Elements, PP Cotton Filter Cartridges For High Flow Filters, Melt Blown Filter Cartridges For Water Treatment, Customizable PP High Flow Multi Cartridge

The melt-blown filter cartridges are divided into six categories based on their appearance and size: flat filters, needle-punched filters, embossed filters, grooved filters, big fat filters.

PP Melt Blown Filter Cartridges, PP Melt Blown Filter Elements For Water Treatment

The melt-blown filter cartridges are divided into five categories based on their appearance and size: flat filters, needled filters, embossed filters, grooved filters, big fat filters.

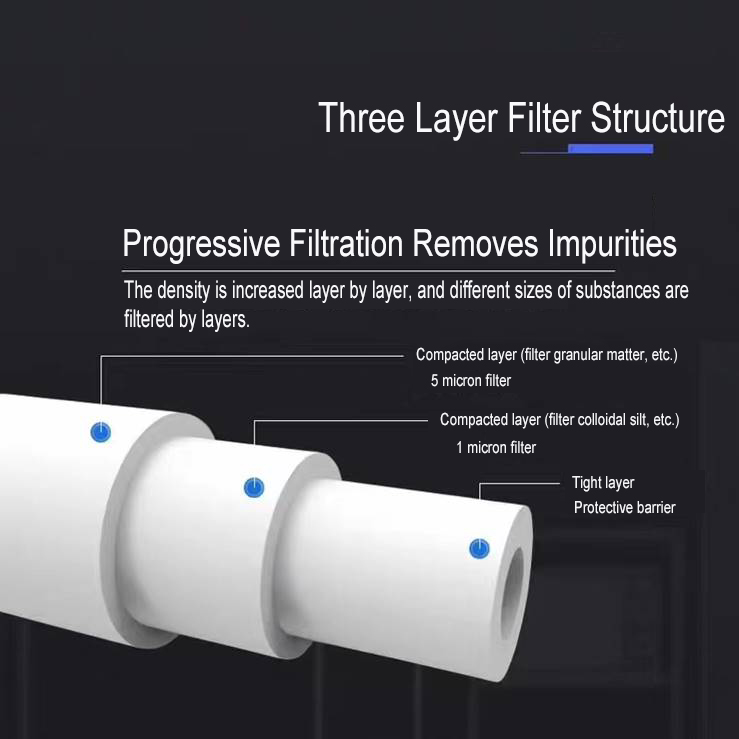

The features of PP melt blown filter cartridges include:

High filtration accuracy, large filtration flow, low pressure, stable efficiency;

Stable controlled filtration accuracy, able to use filter cartridges scientifically according to different filtration requirements;

High dirt-holding capacity and long service life, low cost;

Suitable for filtration of strong acids, strong bases and organic solvents;

Excellent chemical compatibility and strong dirt-holding capacity;

Can be used in various environments, including the pharmaceutical, food, and electronics industries.

Specifications:

Outer Diameter: 42-110mm

Inner Diameter: 20/28/30/34/65mm

Filter Precision: 0.5um, 1um, 3um, 5um, 10um, 20um, 50um, 100um, 150um

Length: 10", 20", 30", 40", 50", 60"

Maximum Operating Temperature: 〈60℃

Operating pressure: 0.1-0.4Mpa

Rated Water Outflow: approx 1.5T/h for 40 inch

Replacement Cycle: 3-6 months

Packaging Details: Carton

The inner diameter, outer diameter, length and label of the filter can be customized.

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail,

Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Precautions:

1. This product uses municipal tap water.

2. The specific replacement cycle varies depending on the water quality and water usage in different areas.