1. Equipment introduction

Mixed bed is short for mixed ion exchange column, which is designed for ion exchange technology. The so-called mixed bed is to mix a certain proportion of cation and anion exchange resin into the same exchange device to exchange and remove ions in the fluid. Because the specific gravity of the cation resin is larger than that of the anion resin, the anion resin is on the top of the cation resin in the mixed bed. Generally, cation and anion resin have a filling ratio of 1:2, there are also filling ratio of 1:1.5, can be considered according to different resin choices. Mixed bed is also divided into in vivo synchronous regeneration mixed bed and in vitro regeneration mixed bed. The synchronous regenerative mixed bed is carried out in the operation and the whole regeneration process in the mixed bed, and the resin does not move out of the equipment during regeneration, and the cation and anion resin are regenerated at the same time, so the auxiliary equipment is less and the operation is simple.

The equipment of mixed bed treatment process includes mixed ion exchanger and in vitro regeneration equipment. In vitro regeneration equipment mainly includes resin separator, anion (cation) resin regenerator, resin storage tower, hybrid resin tower and acid base regeneration equipment. The main characteristics of the domestic mixed bed treatment process are reflected in the resin separation and regeneration process.

The water intake requirements are generally first-level reverse osmosis effluent, and the conductivity is within 10uS/cm; Its water production conductivity is generally ≤0.1uS/cm, that is, the resistivity is ≥10MΩ/cm.

Second, Equipment principle

Basic principles of ion exchange:

Using ion exchange method, the cation and anion can be removed from water. Sodium chloride (NaCl) is used to represent inorganic salts in water, and the basic reaction formula of water desalting is:

1. Cation exchange column: R-H+Na+=R - Na+H+

2. Anion exchange column: R-OH+Cl-=R-Cl+OH-

After the cation and anion exchange column is connected in series, it is called the composite bed, and its total reaction formula is:

R-H+R-OH+NaCl=R-Na+R-Cl+H2O

It can be concluded that NaCl in the water has been replaced by H+ and OH- on the resin respectively, and the reaction product is H2O, so the effect of removing salt in the water is achieved.

3. Mixed ion exchange column (mixed bed) : The remaining salts that have not been exchanged in the cation and anion beds are further removed. Since H+ and OH- that enter the water after mixed ion exchange immediately generate a very low degree of ionization (H2O), there is almost no inverse exchange phenomenon caused by the exchange of the cation bed or the anion bed, the exchange reaction is very thorough. Therefore, the effluent quality of the mixed bed is better than that of the compound bed composed of cation and anion exchange columns in series, and the finished water with high purity can be obtained.

4. Ion exchange equipment is carried out by ion exchange resin in electrolyte solution, which can remove various anions and cations in water, and is an irreplaceable means in the preparation of high purity water process. Ion exchangers are divided into cation exchangers, anion exchangers, etc. When raw water passes through the ion exchange column, the cation in the water and the anion in the water (HCO-plasma) are exchanged with the H+ ions of the cation resin and the OH- ions of the anion resin in the exchange column, so as to achieve the purpose of desalting. Different combinations of cation and anion mixed columns can make the water quality reach higher requirements.

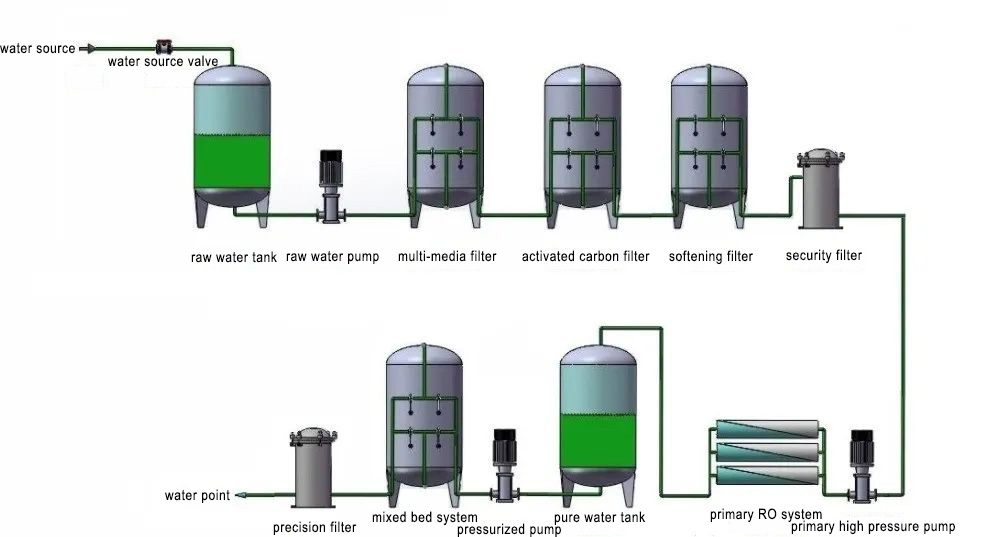

3. Process flow

As in the picture "Process flow chart - mixed bed".

4. Technical parameters

Water production: can order according to the requirements of customers (0.25-300 tons/hour)

Original water source: tap water or groundwater (conductivity less than 400us/cm)

Water production quality: conductivity less than 0.1us/cm (resistivity ≥10MΩ/cm)

Equipment power: 1.5KW-800KW

Running status: Automatic running and periodic backwashing

Backwash frequency varies with inlet water quality (1 ~ 3 days).

Regeneration frequency varies with inlet water quality (7-15 days).

Chemical cleaning depends on membrane material and membrane contamination.

Product features: High integration, stable operation, reliable water quality

5. Application fields

The mixed bed is generally placed after the reverse osmosis device (or directly applied to water with low salt content), and further desalting of water can produce higher pure water, which is widely used in electronics, chemical, atomic energy, electric power and other industries.