FRP (Fiberglass Reinforced Plastic) is a newer composite material used in chemical plant appliances and equipment (such as containers and cans). FRP storage tanks and containers have many useful applications, including industrial and commercial water treatment systems. FRP storage tanks or containers are durable, lightweight, flexible, high strength, corrosion-resistant, and inexpensive. Therefore, such containers are generally considered to be a true substitute for copper containers.

What are the characteristics and advantages of industrial FRP tanks?

Because they do not rust, there is no need to cover up or paint.

FRP has very few problems related to stress, heat, electrical conductivity, and weather conditions.

Compared with similar metal products, they have higher and better corrosion resistance.

FRP tanks and containers are extremely lightweight. They are only 2/3 of the weight of aluminum and only 1/4 of the weight of steel. Therefore, FRP equipment can be handled better.

FRP products are cheaper than metal substitutes. Just like they are almost half the price of steel. Even in extremely corrosive environments, the service life of FRP is at least 5 to 10 times longer than stainless steel.

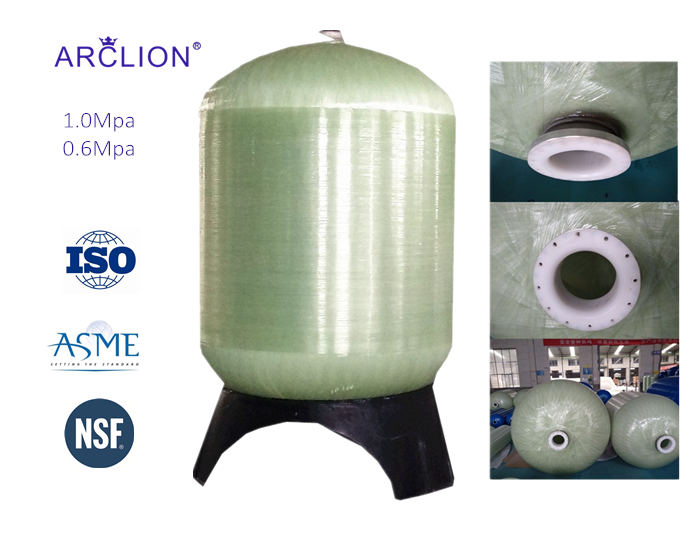

Frp Pressure Vessels/FRP Composite Tanks

FRP equipment is more slip-resistant than metal equipment.

FRP pressure vessels ,FRP Composite Tanks, are now equipped with better resin treatments related to impact, heat, and cracks. Obviously, this encourages the widespread use of top FRP horizontal fuel tank manufacturers and metal substitutes.

They are highly customizable in design.

FRP is not conductive, so there is no risk of electrical equipment short-circuiting.

The addition of brominated materials makes FRP containers flame retardant.

FRP is an efficient insulating material with good thermal expansion properties.

The bottom of the FRP container can track heat well.

There is no flammability trouble when welding.

It does not leave any trace metal contamination in shampoos or antiperspirants.

Its adhesive properties and resin elongation help absorb equipment vibration.

Why is FRP the first choice for manufacturing tanks and vessel(membrane housings)?

FRP is a widely accepted and widely used material, usually used to manufacture containers and tanks used in chemical plants and water treatment systems. The key structure is completed by filament winding. FRP is inherently corrosion-resistant. Even if exposed to liquid, it will not cause corrosion. Moreover, it can effectively withstand hydrostatic pressure and strong pulling force. It is usually better and better than stainless steel. Therefore, FRP is usually selected to manufacture water containers and water storage tanks.

How can FRP storage tanks and containers help water treatment?

As mentioned earlier, FRP is not affected by liquids, water, and irritating chemicals. Therefore, any leading manufacturer of FRP horizontal containers likes to use FRP for water treatment plants. FRP is leak-proof, so it can make the water flow simple and clear. In addition, it is flexible, so it can be given any shape (vertical or horizontal) and size (large or small).