4 INCH END ENTRY MEMBRANE HOUSING FOR RO APPLICATIONS

• Quick lock head retention system for quick access to membranes

• Exteriors coated with high gloss polyurethane paint for UV Resistance

• Winder-G design with burst pressure test 3-4 times of operation pressure for saving cost in need

• More accurate head seal area is formed by mandrel surface

• Head seal is captured, hence doesn’t roll during head assembly fitment

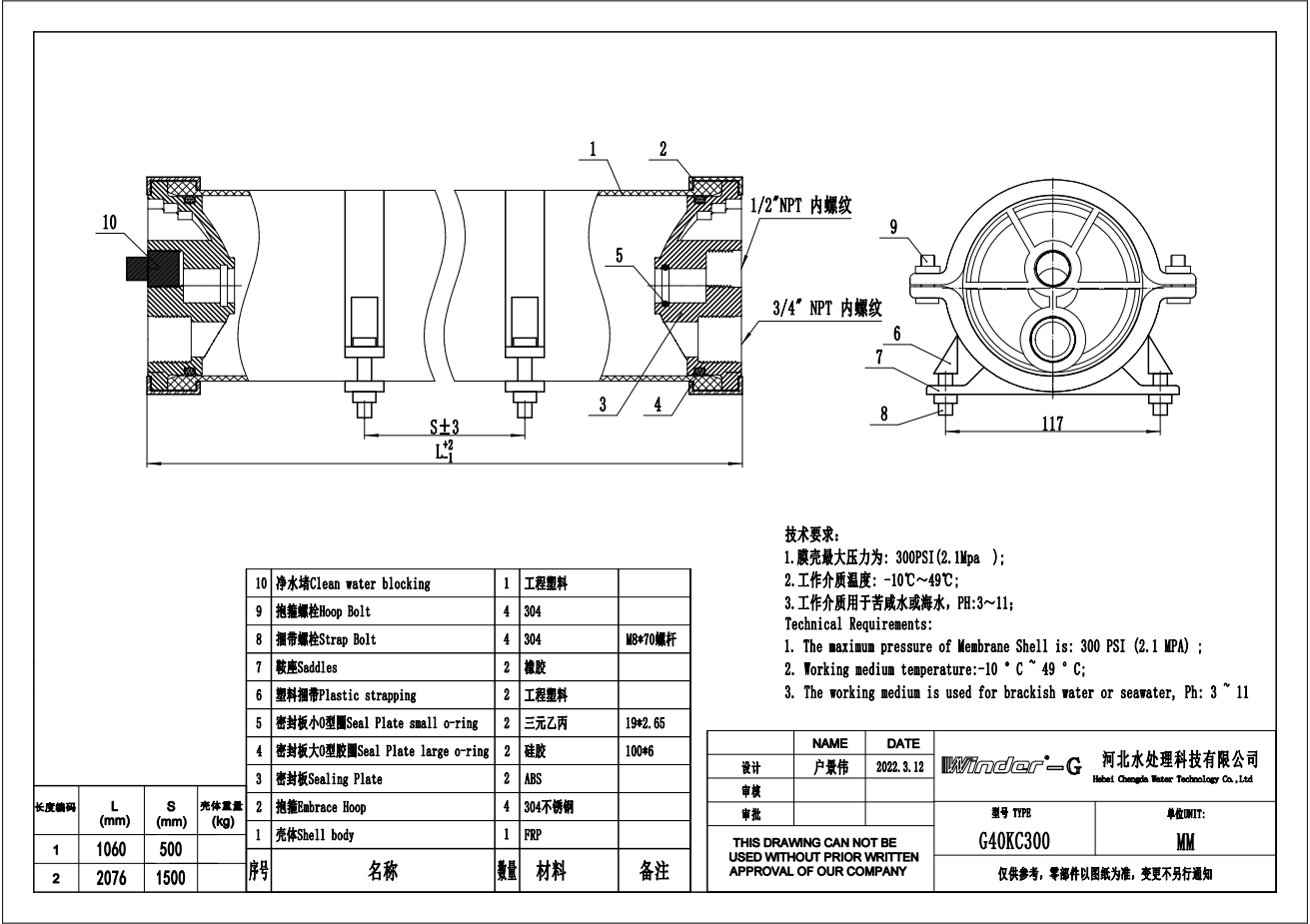

Drawing:

![]() 220913 Drawing of G40KC300-Winder-G FRP RO membrane housings -Chengda Water.pdf

220913 Drawing of G40KC300-Winder-G FRP RO membrane housings -Chengda Water.pdf

G40E300-1,2

General information

| Unique Features

| Certifications

|

Winder-G® G40E Series models are available upto a max operation pressure of 300PSI

These are made up of epoxy / glass composite to meet the demands of long term and continuous use in RO processes. Winder-G 40E Series vessels can accommodate any standard*4” membrane element.

* Standard element length = 40 “ long

| • Mirror finish internal surface for easy & quick loading and unloading of membranes • Quick lock head retention system for quick access to membranes • Exteriors coated with high gloss polyurethane paint for UV Resistance • Winder-G® design with burst pressure test 3-4 times of operation pressure for saving cost in need • More accurate head seal area is formed by mandrel surface • Head seal is captured, hence doesn’t roll during head assembly fitment

| • Winder-G® 40E300: burst pressure 3-4 times of operation pressure compliant • Certified by ASME, ISO9001,ISO14001 and GB/T2800. |

Winder-G 40E Series Specification*

MODEL | PRESSURE | TEMPERATURE | BURST PRESSURE | LENGTH | FEED PORT (inch) | PERMEATE PORT (inch) |

G40E300 | 300 PSI / 20 bar | 120 ˚F / 49 ˚C | 900-1200 PSI / 61-81bar | 1-2 | 1/2” or 3/4" NPTF or BSPP | 1/2” NPTF or BSPP |

* Specifications are subjected to change without prior notice (for more details refer model specific engineering drawings)

Winder-G Burst Test : 3-4 times of its design pressure.

Cycle Test: 100000 times.

Hydraulic Test: 100% leakage test with 1.2 times of operation pressure for each membrane housing, not sampling.

Barcol Hardness Test: Repeated once every 1.5 meters.

DRG REG | QTY | DESCRIPTION | MATERIAL |

1 | 1 | Shell body | FRP |

2 | 4 | Embrace Hoop | SUS304 |

3 | 2 | Sealing Plate | ABS |

4 | 2 | Sealing Plate Big O-ring | Silica Gel |

5 | 2 | Sealing Plate small O-ring | EPDM |

6 | 2 | Straps | Engineering Plastic |

7 | 2 | Saddles | Soft PVC |

8 | 4 | Strap Bolt | SUS304 |

9 | 4 | Hoop Bolt | SUS304 |

10 | 1 | Permeate Port Plug | Engineering Plastic |